Part 1: The Genesis of a Perfect Start

In the vast, complex world of agriculture, a single seed is a promise—a tiny capsule of potential waiting for the perfect moment to awaken. For our protagonist, a humble basil seed, that moment didn’t arrive in a sun-baked field or a traditional greenhouse. It began its life in the pristine, controlled environment of an Infarmight vertical farm. This is not just a farm; it is a sanctuary of precision, a technological marvel where every variable is tuned for optimal growth.

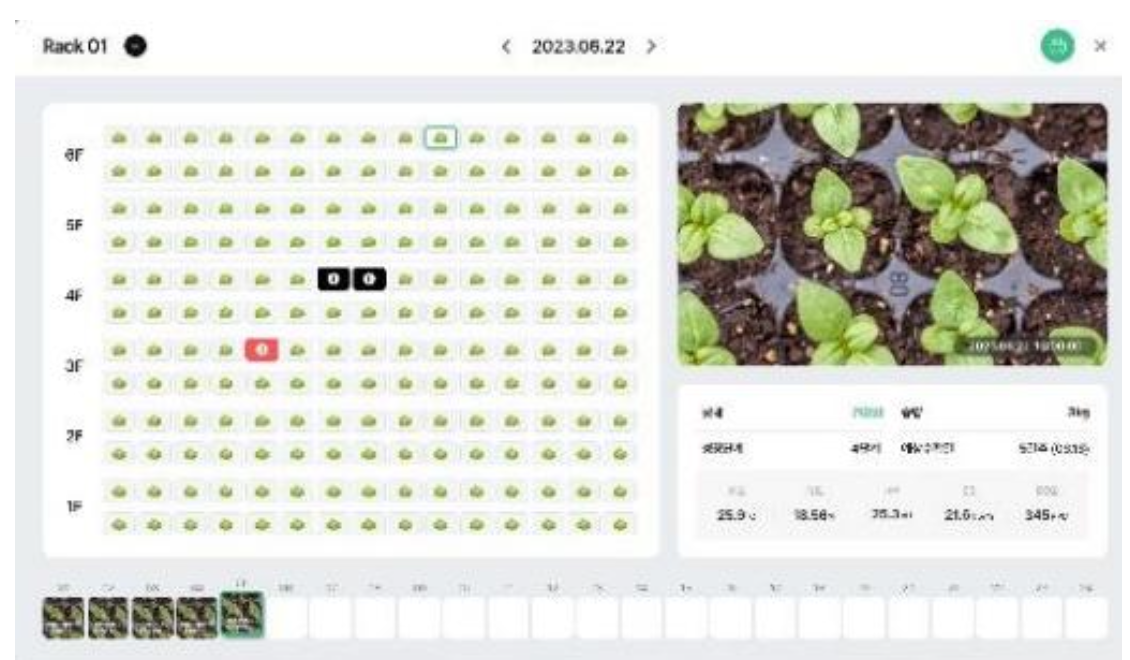

The journey starts not with soil, but with data. Before the seed is even placed, Infarmight’s proprietary AI analyzes hundreds of data points—from the specific cultivar’s genetic profile to the desired nutritional output—to create a bespoke “Growth Recipe.” This recipe dictates the exact light spectrum, humidity level, temperature, and nutrient composition required at every hour of the seedling’s life.

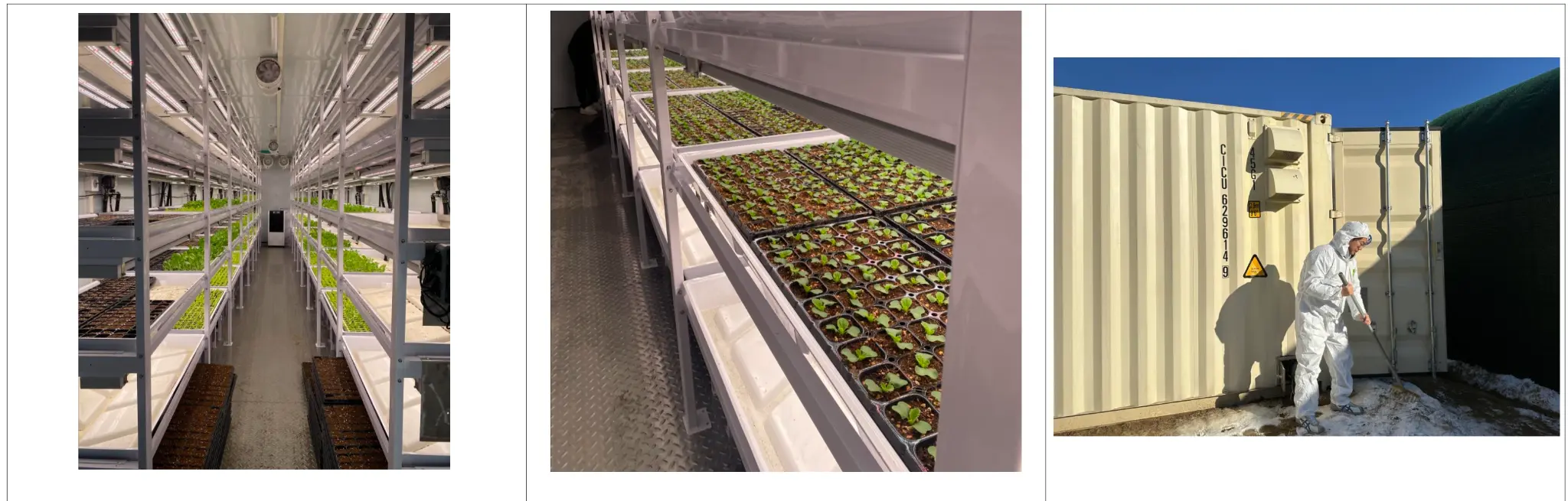

The seed is gently placed into a sterile, inert growing medium, a stark contrast to the unpredictable chaos of the outside world. Here, in the quiet hum of innovation, the promise of perfect produce begins to unfold.

Part 2: The Cradle of Precision

The first sign of life is a delicate, pale sprout, pushing through the medium. This is the seedling’s nursery, a zone of intense, personalized care. Infarmight’s system monitors this critical germination phase with microscopic precision. High-resolution cameras track the cotyledons’ unfurling, while specialized sensors measure the micro-climate directly surrounding the young plant.

In traditional farming, a sudden cold snap or a pest infestation could wipe out an entire crop at this vulnerable stage. In the Infarmight cradle, such threats are non-existent. The environment is sealed, eliminating the need for pesticides, herbicides, or fungicides. The air is filtered, and the water is purified and perfectly balanced.

The seedling’s early days are characterized by a rapid, stress-free development, thanks to the continuous, gentle optimization provided by the Infarmight platform. It is a world of perpetual spring, where the sun never sets and the rain is always the perfect pH.

Part 3: The Ascent and the AI Conductor

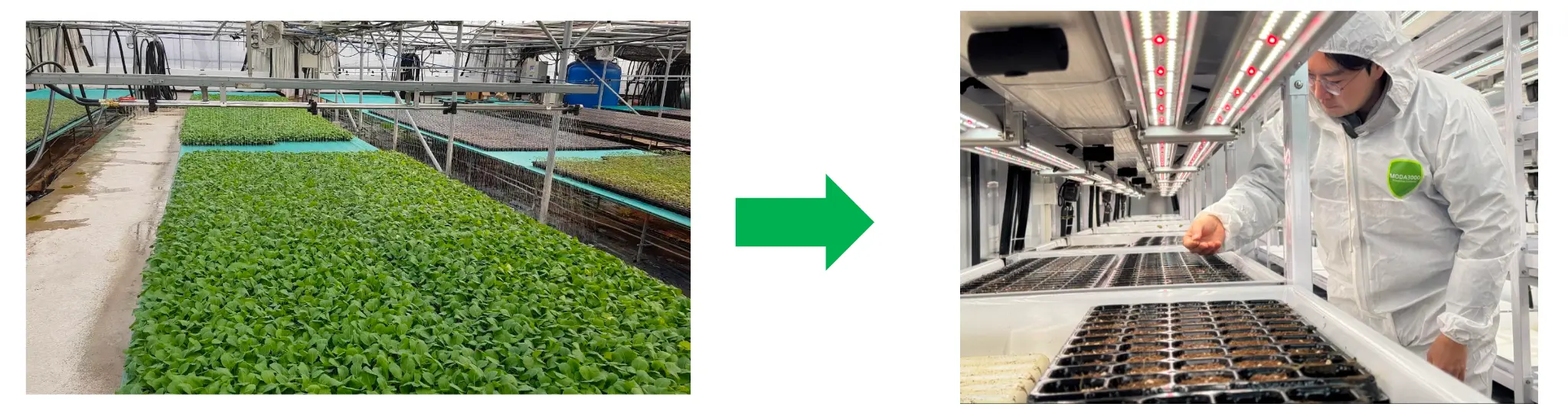

As the seedling matures into a young plant, it is moved to the main vertical growth racks. This is where the true power of Infarmight’s technology becomes apparent. The plant is now part of a vast, multi-layered ecosystem, bathed in the soft glow of LED lights that mimic the most beneficial parts of the solar spectrum.

The core of this phase is the AI Conductor. This machine learning system processes terabytes of data daily, acting as the ultimate agronomist. It doesn’t just react to conditions; it predicts them. If a plant’s growth rate deviates by even a fraction of a percent from the ideal Growth Recipe, the AI instantly adjusts the nutrient flow (hydroponics), the light intensity, or the air circulation.

Consider the stark difference between this method and conventional agriculture:

| Feature | Conventional Farming | Infarmight Smart Farm |

|---|---|---|

| Water Usage | High (Evaporation, Runoff) | Up to 95% less (Recirculation) |

| Pesticides | Essential for crop protection | Zero (Sealed environment) |

| Yield per Acre | Limited by land area/season | Up to 400x higher (Vertical stacking) |

| Nutrient Delivery | Inconsistent (Soil variability) | Precision-dosed, real-time adjustment |

| Climate Risk | High (Drought, flood, frost) | Zero (Controlled environment) |

This precision ensures that the plant grows not just quickly, but with maximum nutritional density and flavor. The plant’s roots, suspended in the nutrient-rich water, are a testament to this efficiency, growing strong and white, absorbing exactly what they need, when they need it.

Part 4: The Moment of Perfection

The journey culminates in a state of absolute perfection. The basil plant, now fully mature, is a vibrant green, its leaves fragrant and perfectly formed. The AI Conductor has guided it to its peak, ensuring that the flavor profile—the delicate balance of volatile organic compounds—is exactly as the Growth Recipe intended.

This is the moment of harvest, and it is a process as precise as the growing itself. Unlike field-grown produce, which must be harvested based on a calendar date, Infarmight produce is harvested based on its biological readiness. The AI signals the exact hour when the plant has reached its optimal state.

The harvest is automated and gentle, minimizing handling and preventing bruising. This immediate transition from the growing rack to packaging is crucial. It locks in the freshness and the nutritional value, a stark contrast to the days or weeks of travel and storage that often degrade conventional produce.

Part 5: The Journey to the Supermarket

The journey from the farm to the supermarket is often the most destructive part of the food supply chain. For our Infarmight basil, this journey is measured in hours, not days. Because Infarmight farms are strategically located within or near urban centers—often in repurposed warehouses or even directly inside grocery stores—the “food miles” are drastically reduced.

This hyper-local model has profound implications for both the product and the planet.

| Metric | Traditional Supply Chain | Infarmight Hyper-Local Model |

|---|---|---|

| Food Miles | Hundreds to Thousands | Tens (or Zero) |

| Shelf Life | Reduced by transit time | Maximized (Harvested at peak) |

| Carbon Footprint | High (Transportation, Cold Storage) | Significantly Lower |

| Food Waste | High (Spoilage during transit) | Minimal |

The packaged basil arrives at the supermarket shelf still vibrant, still breathing, and still bursting with flavor. For the consumer, this means a product that is not only fresher but also more trustworthy, having been grown under transparent, controlled conditions from start to finish.

Part 6: The Vision for a Sustainable Future

Our single basil plant’s journey is a microcosm of Infarmight’s larger vision: to revolutionize the global food system. By decoupling food production from climate, geography, and season, Infarmight is building a resilient, sustainable, and equitable food future.

The technology is not just about growing better plants; it’s about optimizing resource use. The closed-loop system conserves water, the vertical stacking maximizes space, and the AI minimizes energy consumption by precisely controlling the light and climate. This is agriculture as a service, a highly efficient, scalable model that can feed growing urban populations without straining the planet’s finite resources.

The next time you encounter a perfect, vibrant piece of produce, consider its journey. If it came from an Infarmight farm, you are not just holding a plant; you are holding the result of a perfectly orchestrated life, a testament to the power of technology to harmonize with nature, and a glimpse into the future of food.